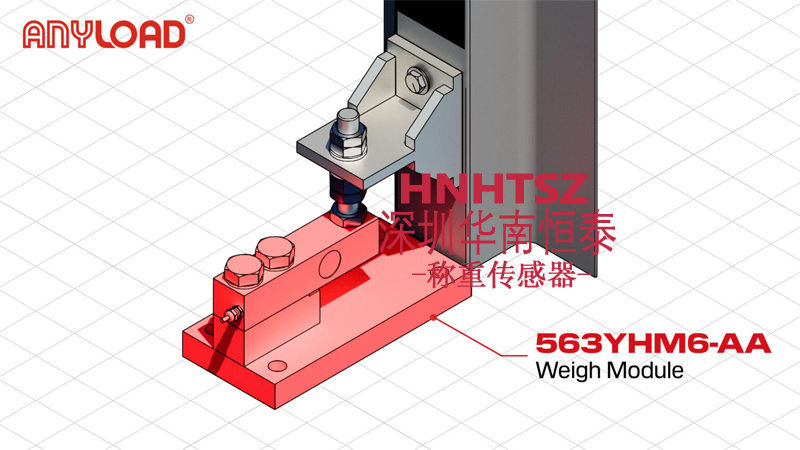

The authorized Chinese agent of ANYLOAD, Shenzhen Huanan Hengtai Industrial Co., Ltd., recommends to you the ANYLOAD silo weighing system 563YHM6-AA self-lifting weighing module. This module employs advanced sensor technology to ensure accurate and error-free data, and it is structurally sturdy and durable.

Industrial Weighing Revolution: Unveiling the Engineering Wisdom of ANYLOAD Silo Weighing System

In industrial scenarios such as chemical production and grain storage, the stability of the weighing system is like the foundation of a building - it directly determines the safety and efficiency of production. When traditional weighing solutions encounter problems such as limited space for silo renovations, corrosion in outdoor environments, and operations in explosion-proof areas, ANYLOAD's 563YHM6-AA self-lifting weighing module system provides a highly innovative solution.

1. Modular design for redefining the installation logic

The traditional weighing renovation of silos usually requires the use of cranes to dismantle the equipment, similar to the need for large machinery when disassembling a precision clock - this not only increases costs but also poses safety risks. The hydraulic synchronous lifting technology of the 563YHM6-AA module is like installing a "factory jack" for the silo. Through a structural design that directly fixes to the support legs of the storage tank, operators can precisely lift the silo body like adjusting the height of a car chassis, completing the sensor installation without the need for external lifting equipment. This "in-situ renovation" mode shortens the renovation period by more than 40%, especially suitable for renovation scenarios with limited space such as pharmaceutical workshops.

II. "Hexagonal Warriors" in the Field of Sensors

The performance chart of the 563YH-23 weighing sensor can be regarded as the benchmark for industrial measurement:

Precision dual certification: Meets both NTEP III level (North American Trade Standard) and OIML C4-C6 level (International Legal Metrology Standard), equivalent to achieving the precision requirements of a sprint in a marathon race.

Safety protection package: ATEX and FM dual explosion-proof certifications, making it as reliable as a fire-fighter wearing an explosion-proof suit in environments such as flour mills where there is a risk of dust explosion. Its IP67 protection level design can also withstand outdoor rainstorms - tests have shown that this sensor can still maintain stable data even during a simulated typhoon-level spray test.

Mechanical optimization innovation: The unique anti-lateral load design effectively resolves the lateral force interference caused by material flow in the silo. Similar to the seismic bearings in buildings, this structure can absorb 80% of non-axisial loads, ensuring that the measurement benchmark remains intact.

III. The Intelligent Evolution of Junction Boxes

The design philosophy of the J04EP-E/J04ES-E junction box is "simplifying complexity":

Topology reconfiguration capability: Supports the parallel calibration of four sensors, akin to a conductor coordinating multiple musical sections. In the eight-leg structure of a large storage tank, the modular installation ensures a horizontal line and enhances the overall accuracy of the weighing system.

Environmental Adaptation Intelligence: The built-in moisture-proof ventilation holes draw inspiration from the altitude pressure regulation principle. In open-pit mining areas with significant temperature differences between day and night, they can automatically balance the pressure difference between the inside and outside of the box, preventing circuit failures caused by condensation. Its modular expansion interface also supports the integration of a temperature and humidity compensation module, making the system a smart terminal that can "think independently".

Stability performance upgrade: Utilizing high-density shielding materials, it effectively resists electromagnetic interference and ensures stable signal transmission. Even in rainy weather, it can maintain zero error in data transmission, significantly enhancing the reliability of the equipment in complex environments.

IV. Verification of the Value of Engineering Practice

In the actual measurement cases of the oil sands mining areas in Canada, compared with the traditional methods, the maintenance period has been extended from 3 months to 18 months. Combined with the "matching output" rapid replacement technology, the downtime for maintenance is controlled within 4 hours. This design, which combines the rigorousness of the German VDA quality system with the lean production philosophy of Japan, is precisely the foundation for ANYLOAD to serve top clients such as Siemens and China Aerospace.

Conclusion: The New Paradigm of Industrial Measurement

The ANYLOAD silo weighing system is essentially a prime example of converting engineering physics principles into industrial aesthetics. The mechanical innovation of the 563YHM6-AA module, the material breakthrough of the 563YH-23 sensor, and the electronic intelligence of the J04EP-E junction box, forming a technical triangle, are rewriting the technical standards in the field of industrial weighing. For enterprises seeking intelligent upgrades of existing equipment, this system is not only a measuring tool but also a precise key to opening the door to Industry 4.0.

Contact: Tina

Phone: 13928483791

Tel: 0755-29660599

Email: sales@hnhtsz.com

Add: Room 609, Building A, Senhai Nuoweijian Industrial Park, No. 7 Jintai Road, Longteng Community, Shiyan Street, Bao 'an District, Shenzhen